ENGINEERING AT ITS BEST

services: ENGINEERING

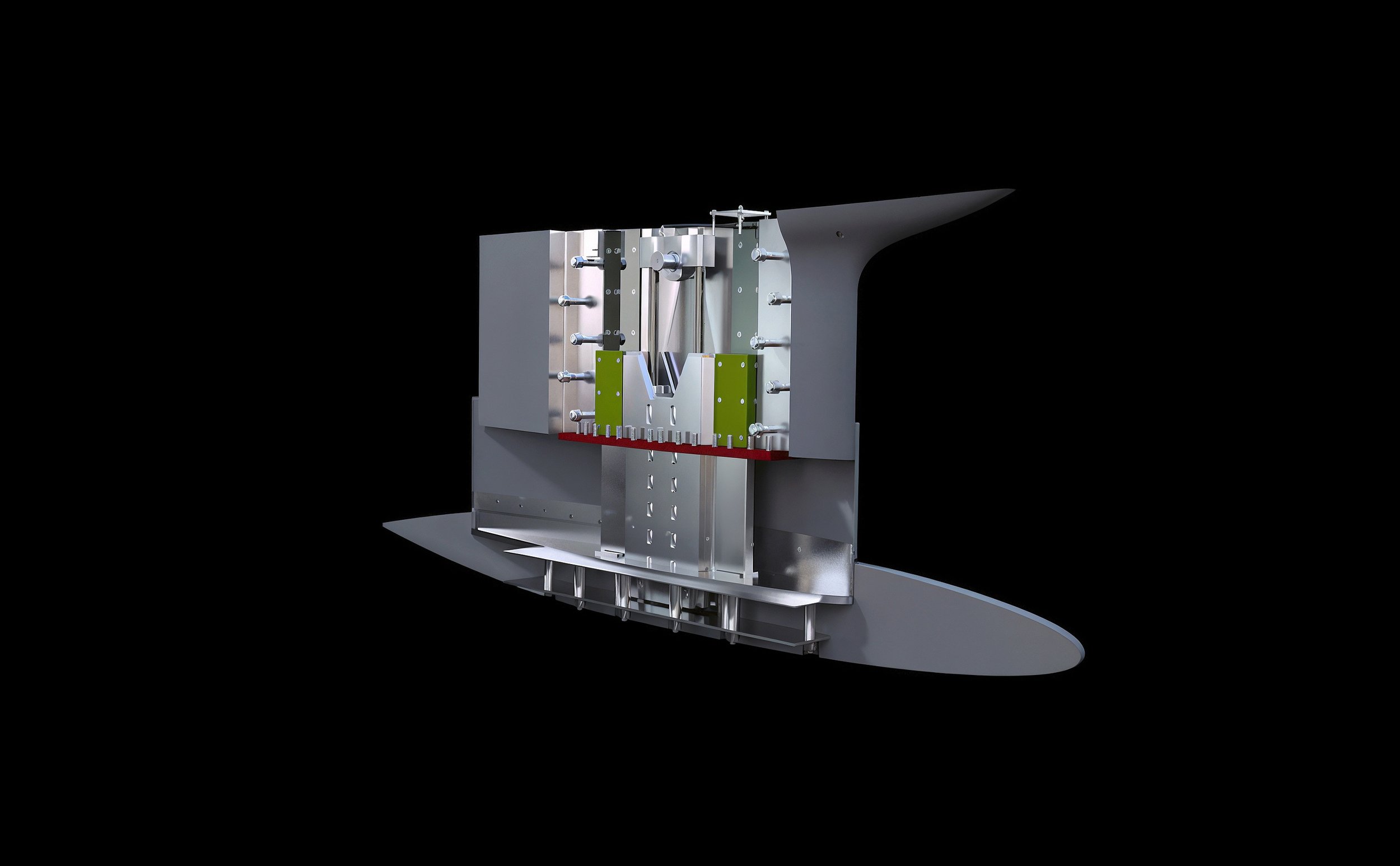

3D Modeling With Extreme Precision.

Our engineers are proficient in using the latest 3d modelling technologies available today, ensuring short engineering periods and a very precise build – saving your time and money. The know-how and experience accumulated in the past three decades of work in the composites field allows us to take on any challenge. Whether marine-related or not, we have the technology, brain- and man-power to be competitive in any part of the business where design and tooling are required.

Engineering Of The Yacht

A product designed and engineered for production leads to efficient manufacturing and profit margin. Proper integration and optimization of all aspects of engineering is crucial. We are in the best position to apply world’s best practices of technologies and build methods – applied to the client’s best tradition and skills. The products are easy to build – and of unbeatable value.

COMPOSITES

The best GRP technology – or the best set of technologies – is chosen to arrive to a light, strong and competitive product. Epoxy, vinyl ester and polyester resins with glass, carbon or Kevlar® reinforcements are applied in a range of technologies from prepregs, SPRINT, RTM, resin infusion or hand lay-up as needed.

DECK GEAR, RIG, KEEL AND SAILS

Our extensive experience throughout the industry leads to better and cost-effective ways to design and engineer these areas. Connected to expertise and tradition of our clients we design innovative solutions which work and are easy to build.

SYSTEMS:

- Engine, Drives And Propulsion

Optimized propulsion system is designed and engineered – from outboard to I/O, inboard straight shaft or V drive and pod systems like IPS or Zeus. J&J has a close relationship with major manufacturers of engines and propulsion gear, including 3D libraries and contacts to appropriate development engineers.

- Woodwork

Detailed drawings of woodwork are produced including files for direct application on the wood processing machinery of the client or of the chosen supplier – in the appropriate software. Modular design and engineering of interior woodwork allows our engineers to develop faster while giving the builder the opportunity to shorten the build times, control the build process and have free hands in choosing the supplier of the wanted products or semi-products.

- Electrics and Electronics

J&J typically produces detailed wiring diagrams and electrical system drawings enabling the client to execute the out-of-the-boat preparation of the system and efficient assembly. This area is developing fast so latest solutions are used to optimize the product. A permanent supply of AC 220 or 110 V is a necessity – and we have excellent solutions to provide this feature.

- Hybrid and Electric

J&J Design is a leader in the field of hybrid technologies: from energy storage and management to intelligent use through the latest in hybrid drive technologies. Custom hybrid drive systems are being developed for boat builders.

- Hydraulics and Water Systems

Design and engineering of this system offers energy-efficient powered functions throughout the boat.

- HVAC

This area became very important with climatic changes and the general use of air conditioning systems in the life of the modern world. J&J has pioneered the standard use of energy-efficient and reliable household A/C systems on boats, connected to the Lithium battery pack which enables noise- and vibration-less nights in a conditioned environment.

- Communication and Entertainment

A smooth liaison of your home comforts and the boat calls for a sophisticated, reliable and price-efficient entertainment system which easily integrates all sources of information. Permanent and good-speed internet has the same priority. J&J engineers production-friendly and cost-effective systems which provides the comfort of your home on your boat.

INTERIOR AND MOCK-UPS

Our expertise lies in understanding small spaces and volumes available on any boat. However, only a mock-up allows to fully understand the validity of design solutions and the best ways how to improve them. We systematically provide and study with our client inexpensive full-scale mock-ups which result in optimized convenient, comfortable and easy-to-build interior solutions lasting the life of the product.

SAFETY

Ergonomics and safety on the boat is our prime concern protecting the boater in all conditions while providing comfort and convenience.

Engineering of Production

A product designed and engineered for efficient production can only shine in adapted production environment. That is why we help our clients to develop purpose/organized production layout and stream which shortens production time and gives yachts of superior quality and reliability.

GRP

Efficient in-house GRP production is the key to competitive products under 60 feet. Best solutions are designed and engineered together with the client to obtain optimized technology, product flow and skill set. J&J has rich experience in introducing new technologies to the client, including training and pre-series supervision.

PRE-ASSEMBLY, MODULES

J&J Design introduced the modular build concept in 1985 and has over decades achieved a high proportion of assembly work to be performed outside the boat.

Many major boat builders today use our modular build technology. The customized solution of this system is adapted to the client’s needs – and limitations.

ASSEMBLY, FLOW STATIONS

The assembly area is where most man hours can be gained. By removing the assembly work out of the boat less time and less effort are spent while increasing the quality of the yacht. We design dedicated assembly flow streams which give best production result while keeping CAPEX low and taking the existing infrastructural limitations in account.

VALUE STREAM

The production process is broken in phases (up to several hundred) and production time together with necessary skill of the worker is projected. This allows us to evaluate all elements of value stream mapping and optimize the production flow in time and efficiency while reducing the financial impact of production tools and working capital.

TOOLS AND ENGINEERING

Production tools must be engineered to support the designed production process and the products developed for this production process. Our job is to design the tools which are efficient in production, easy to produce and minimize the CAPEX spending.