DESIGN

SERVICES: DESIGN

Design Without Compromise

At J&J Design, our design services represent the pinnacle of innovation in maritime engineering, combining years of expertise with a forward-thinking approach to create vessels that are both timeless and revolutionary. Our suite of services encompasses the entire design lifecycle, ensuring that every project benefits from our comprehensive oversight and creative input.

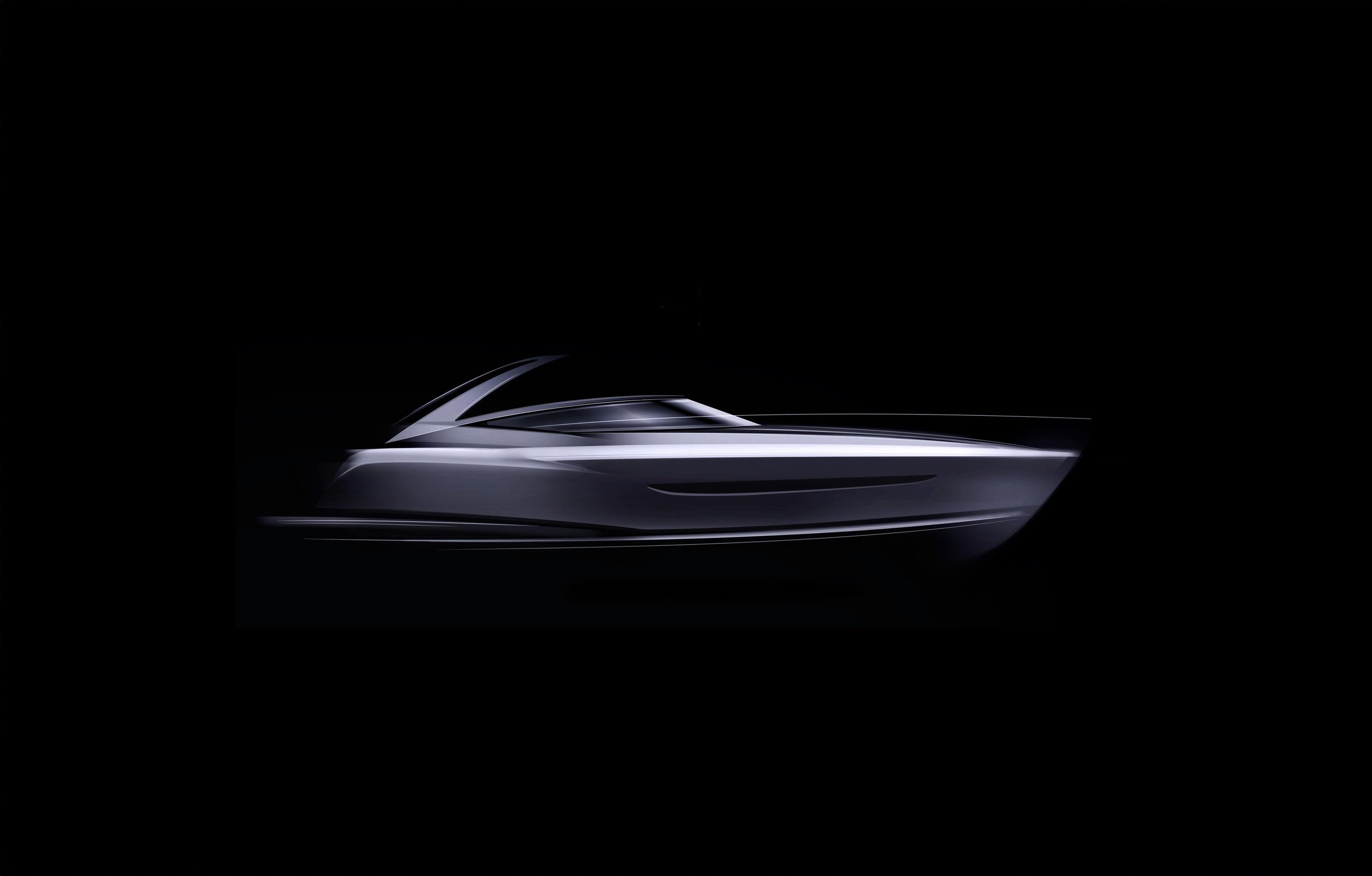

Conceptualization and Sketching:

At this stage at J&J Design, the creative journey begins with transforming initial ideas into tangible sketches, setting a project's foundational direction. This vital phase bridges visions with practical design paths, where the team's creativity converges with client aspirations. Through dynamic sketches, designers explore various aesthetics and functionalities, ensuring concepts are both innovative and aligned with the client's goals. This early feedback loop is crucial for refining ideas, facilitating a seamless transition from abstract concepts to detailed plans, laying the groundwork for successful, client-centric yacht designs.

3D Design and Modeling:

At J&J Design, our 3D Design and Modeling stage is where innovation takes form, utilizing advanced technology to refine every aspect of a yacht's design. This process transforms concepts into precise, digital models, allowing for meticulous refinement of spatial arrangements, aesthetics, and functionalities. Key components include:

Rapid Prototyping: Accelerates the design process, swiftly bringing concepts to tangible reality, enabling practical evaluation and adjustments.

Detailed Renders: Offer a visually rich and realistic preview of the final product, capturing the essence of the design with high fidelity.

Virtual Reality (VR): Provides an immersive experience, allowing clients and designers to explore the vessel's dimensions and design nuances in a lifelike environment, facilitating a deeper understanding and connection with the project before physical construction commences.

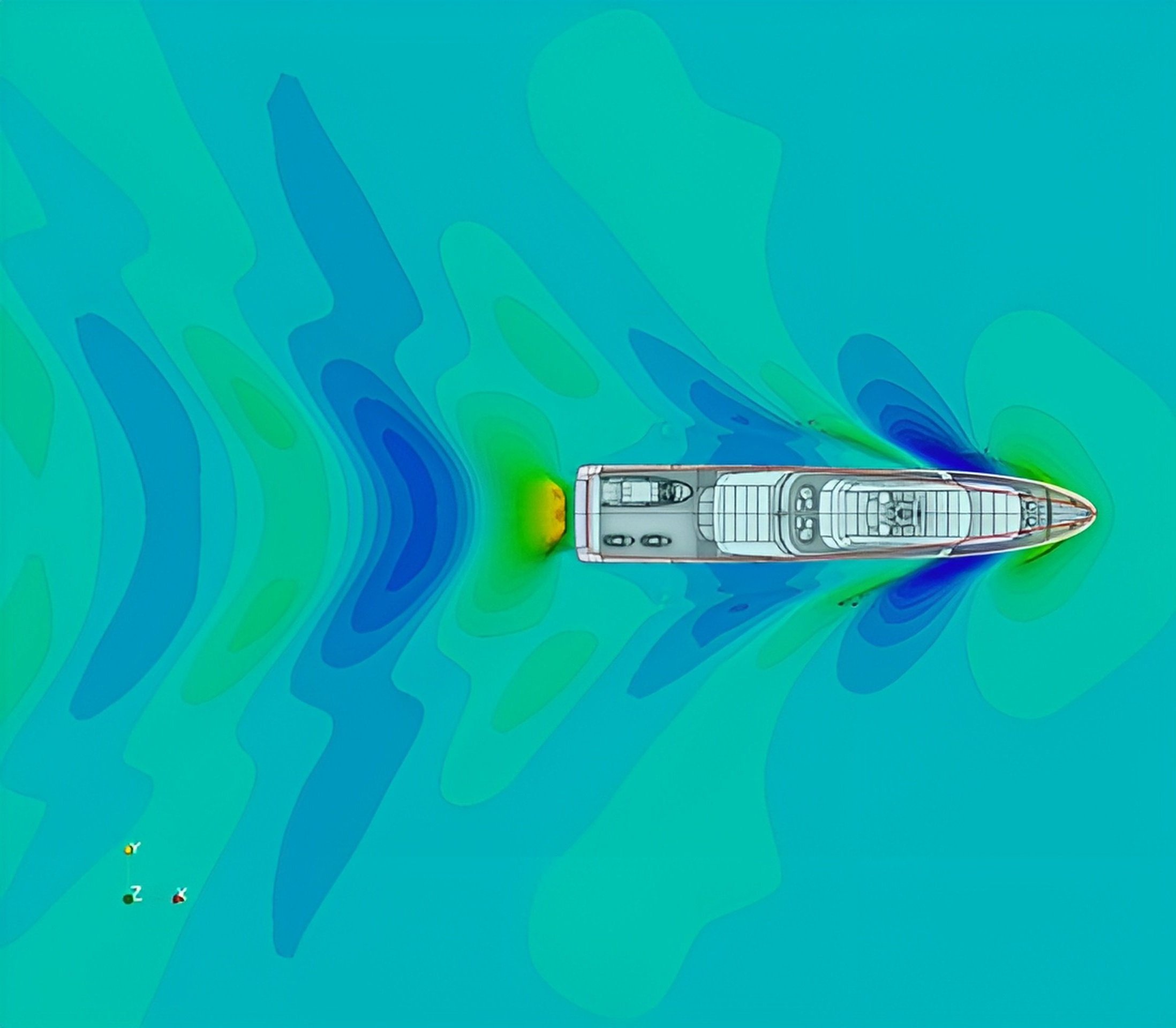

Naval Architecture Enhanced by Advanced Technologies

At J&J Design, our naval architecture is distinguished by its integration of Computational Fluid Dynamics (CFD) and Extensive Tank and Field Testing (ETFT), ensuring our designs not only promise but deliver optimal performance, efficiency, and seaworthiness.

CFD: Central to our design process, CFD simulates fluid flow around yacht surfaces, optimizing hull design for speed, reduced drag, and fuel efficiency. These simulations allow performance refinement under varied conditions well before physical prototypes are developed.

ETFT: Complements CFD with real-world validation, through both controlled tank experiments and rigorous field trials, ensuring our designs meet performance, stability, and safety expectations.

This combination of cutting-edge CFD analysis and comprehensive ETFT ensures that every yacht designed by J&J Design embodies the pinnacle of modern naval architecture, marked by an unwavering commitment to innovation, efficiency, and sustainability.

Sustainability Integration

J&J Design integrates sustainability at every design stage, emphasizing key practices for environmental stewardship:

Use of Sustainable Materials: We go beyond just selecting eco-friendly materials by focusing on durability and efficiency, reducing environmental impact without compromising on aesthetics or quality.

Energy-efficient Designs: Our designs feature solar panels, hybrid propulsion systems, and other technologies to enhance energy efficiency, demonstrating our commitment to sustainability and leading the green boating movement.

Custom Green Solutions: Acknowledging each client's unique environmental aims, we provide tailored solutions from the project's outset, ensuring sustainability is a core design principle.

This approach underlines J&J Design's leadership in sustainable maritime design, continually advancing industry standards for innovation and environmental responsibility.

Consultancy and Market Analysis

J&J Design's consultancy services are anchored in comprehensive market research and analysis, delving into trends, customer behaviors, and innovation opportunities. Our approach encompasses detailed

feasibility studies,

evaluations of production methods, and

profitability analyses,

ensuring projects are not just imaginative but also practical and market-ready. This depth of insight enables us to advise on strategic decisions, optimizing design and production for market success while aligning with the visionary goals of our clients. Our consultancy aims to bridge the gap between creative ambition and commercial viability, making each venture not only a design triumph but a market success.

Preliminary Costing and CAPEX Analysis

J&J Design's approach to Preliminary Costing and CAPEX Analysis is founded on a deep comprehension of yacht production's financial intricacies, guiding us to recommend cost-effective yet high-quality design solutions. Our expertise in early-stage costing and business case evaluation plays a critical role, ensuring each project's economic viability from its inception. This method includes detailed assessments of production costs, materials, labor, and overheads, alongside a strategic analysis of investment (CAPEX) requirements.

By integrating these financial insights, we ensure that every project not only achieves its visionary design objectives but also stands on a robust financial foundation, promising profitability and market competitiveness.

This expanded focus on financial soundness throughout the design and production process underscores our commitment to delivering projects that excel in both form and function, aligning with our clients' financial strategies and market positioning goals.

Our team at J&J Design is dedicated to pushing the boundaries of yacht design, blending artistic vision with technical mastery to create vessels that redefine maritime luxury and sustainability. With over 340 projects delivered to more than 55 production boat builders across 22 countries, our legacy is a testament to our commitment to excellence and innovation in every endeavor.